How a Ventilex Fluidized Bed Dryer works

Working principle of the Ventilex Fluidized Bed Dryer: In a fluidized bed dryer, a product or solid is made fluid by an upward-moving flow of gas.

The mechanical movement of the fluidized bed dryer strengthens this effect. This results in an optimal mix of gas and product so that high heat transfer and an optimum physical reaction speed are achieved.

By choosing the right combination of gas speed and mechanical movement, you can process granular products with a wide range of grain sizes successfully. While minimizing dust and fines, increasing yield.

Ventilex Fluid Bed Dryer features

- A mechanically simple, dependable, and reliable transport design

- An exclusive “shaking” motion that allows first-in, first-out drying of products. Heat time and temperature are controlled to create the most desirable effect

- Consistent, predictable results that are never over or under dried

- Fluidization or sub-fluidization of your product (when longer times in the dryer are needed), allowing for precise control of process-required plug flow characteristics

- Heavy duty, robust product transport that assures low-maintenance, dependability, and long equipment life

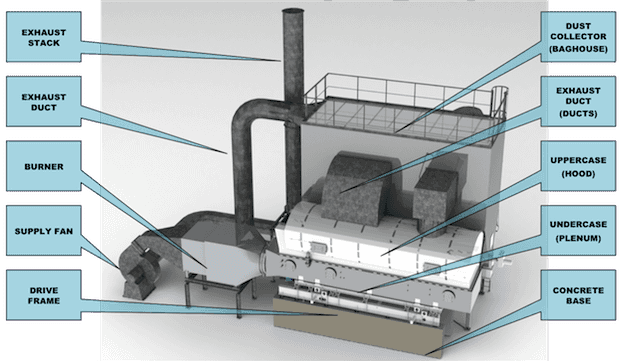

Complete Ventilex Fluid Bed Dryer System

Ventilex high temperature design Fluid Bed Dryer

Ventilex Fluid Bed Dryers operate at temperatures ranging from -15° C to +600° C [5° to 1112° F] with gas speeds varying from 0.2 to 3 m/sec. We are the only fluid bed dryer manufacturer delivering a product capable of achieving steady state air temperature drying of 600° C [1112° F]!

These high temperatures result in more drying air volume, which means greener, more sustainable process characteristics and remarkable energy efficiency. Ventilex systems energy efficiency results in lower operating costs for your process, while our simple drive, high quality materials, and minimal dust or fines formation lower maintenance costs and increase yields, as well.

We engineer fluid beds for all different types of applications. Knowing that no two applications are exactly alike, we take an engineered and systems approach for each installation. For food, dairy and hygienic applications, we offer our CIP (Cleaning-In-Place) design. For inert materials, we offer our high temperature design. Ventilex takes pride in matching our design to your fluid bed dryer needs, which results in cost savings for you.

Ventilex custom designs and builds a fluid bed dryer, cooler, or sterilizer to meet your requirements, no matter how strict.

Your own Ventilex Fluid Bed Dryer?More features of Ventilex Fluid Bed Dryers:

- Engineered for specific products

- High energy efficiency that can save 40-60% or more on steam/gas/oil costs

- Use of shaking, not vibration, so there are fewer moving parts and less maintenance

- Air drying temperature up to 600° C [1112° F]

- Fully automatic operation

- Sub-fluidization plug flow and first-in, first-out technology

- Gentle on materials

- Well-mixed fluidization, which covers the entire spectrum and is able to accurately control the spread of residence time

- Designed to withstand the harshest applications

- Compliant with criteria for hygiene and cleanliness in the dairy, food, and pharmaceutical industries

- Complete CIP-able with full drainage. There are no cracks, no corners, and no product buildup points on designs that are based on USDA and FDA guidelines