Fluidized bed dryers: future-proof your sugar drying process

With consumption expected to exceed production 2020, the future looks bright for the sugar industry. However, sugar prices are expected to drop, while sustainability demands increase. How should sugar production companies respond? More specifically, how can they adapt their sugar drying solutions to increase production efficiency while reducing costs and carbon footprint? The answer, we pose, is to use a fluidized bed dryer.

Sugar production, consumption and customer expectations

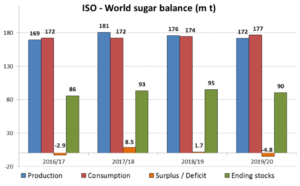

According to the European Commission, global sugar production is expected to decrease with 4 million metric tons (MT) to 172 million MT in 2019/2020. By contrast, the EC expects consumption to increase to 177 million MT.

Global sugar production and consumption – European Commission, October 2019

While this sounds like good news for sugar manufacturers, there is a catch. Statista.com has computed that between 2016 and 2026, the global price of sugar is expected to decrease from $ 0.17 per pound to $ 0.14. If companies wish to fulfill their growth objectives, they will have to increase production efficiency, or reduce costs. Or both, but we will get to that in a moment.

And there is more. Sugar production requires large amounts of energy, thus creating a massive carbon footprint. Customers and governments worldwide are aware of this, and, as is the case in other industries, their call for sustainably produced sugar is growing louder.

Manufacturers have no choice but to respond. How can they future-proof their drying process?

The sugar refining process

Sugars are found in the tissues of most plants. However, they are only present in sufficient concentrations for extraction in a number of crops. Sugarcane makes up for 80% of the total sugar production, sugar beet accounts for the remaining 20%. Alternatively, some sugar is extracted from date palm, sweet sorghum and sugar maple.

Cane sugar does not strictly need refining. However, in many cases the molasses (which gives sugar more color), is removed to create the white sugar households and food producers are accustomed to. By contrast, beet sugar does require refining, as the raw sugar has a strong beet flavor.

The sugar refining process steps

The affination process

- The raw sugar is mixed with syrup.

- The srup is centrifuged to wash away the outer, less pure coating of the raw sugar crystals.

Alternatively, sugar refineries buy high pol sugar to omit the affination process.

The sugar refining process: clarification and concentration

- The sugar is dissolved.

- Phosphoric acid and calcium hydroxide are added to precipitate calcium phosphate. These particles entrap some impurities and absorb others, and then float to the top of the tank.

- The calcium phosphate particles are skimmed off and any remaining solids are filtered out.

- The clarified syrup is decolorized by filtration through a bed of activated carbon or, in more modern plants, ion-exchange resin.

- It is concentrated by boiling.

Cooling and crystallization

- The concentrated syrup is cooled and seeded with sugar crystals, which cause the sugar to crystallize.

- It is centrifuged to separate the sugar crystals from the mother liquor.

- The wet sugar is dried before storing

The sugar drying process

Sugar producers can reduce their footprint with various measures, ranging from crop rotation and recycling of organic matter to reductions in chemical use and improved energy use.

In this article, we will focus on the sugar drying process. Drying is vital to create high-quality sugar. After all, if sugar were to be stored with relatively high amounts of moisture, the water content inside the sugar crystals would slowly migrate to the outer surface, leading to clumping and discoloration.

To ensure optimal product quality, the sugar is therefore dried in sugar drying equipment such as a (conveyor) belt, rotary drum, spray dryer, or (vibro) fluidized bed dryer. But not all of these methods are equally preferable.

The rotary sugar dryer

In a rotary sugar dryer, for instance, sugar is dried in countercurrent or co-current air flows, while tumbling through the rotating, cylindrical drums. Rotary drum dryers are not prone to stickiness or clumping. However, fine, low-weight sugar particles might be entrained with the gas or air that flows through the dryer.

Moreover, rotary sugar dryers consume high amounts of energy, driving up costs, and carbon footprints.

The (conveyor) belt dryer

Alternatively, sugar can be dried in a (conveyor) belt dryer, which transports the sugar on a belt, while hot air is pressed through the bed. Belt dryers generate uniform output, ensuring good sugar quality. Moreover, an added heat recovery system can decrease energy use.

Unfortunately, a belt dryer is large and takes up much space. Therefore, this drying unit is not suitable for smaller production plants, nor can it easily be added at a later stage.

Sugar spray drying

In a spray dryer, the wet sugar is dispersed into controlled spray, which is dried in hot air or gas. Although spray drying is highly preferable in many food products, it is less suitable for sugar drying. While being spray dried, the sugar particles stick together and to the nozzle, causing clogging. As a result, the product quality is compromised, product losses are ample, cleaning sessions are frequent, and cleaning costs are high.

The vibro fluidized bed dryer

Sugar can also be dried in a vibro fluidized bed dryer, also called a VFBD dryer. In this type of fluid bed dryer, a vibrating conveyor moves the product through the dryer, exposing it to updrafts or air or gas. It is through this air or gas that the sugar is brought into a liquid state, causing high heat transfer that is enhanced by the vibrating motions.

Vibro fluidized bed dryers are highly efficient. They generate uniform results without the risk of stickiness or sugar clumping, and without the excessive entrainment losses of rotary dryers. Contrary to (conveyor) belt dryers, the vibro fluidized bed dryer is smaller and, therefore, more space-efficient.

We strongly believe there is only one undeniable disadvantage to this highly efficient drying installation: the dryer is subjected to significant g-forces, leading to swift wear and tear and high maintenance costs.

The shaking fluidized bed dryer

That leaves us with the shaking fluidized bed dryer. As is the case with the vibro fluid bed dryer, sugar is fed into the dryer and conveyed over a perforated plate under which heated air is supplied. The working of a fluid bed dryer is such, however, that instead of creating vibrations, this fluid bed uses a gentle shaking motion to move (fluidize) the sugar, thus avoiding the damaging g-forces. As a result, the shaking bed has all the advantages of a vibro fluid bed, but has a decidedly longer life span and requires less maintenance.

The response of the sugar manufacturer…

And that is the answer to manufacturers who wish to future-proof their drying process: the shaking fluidized bed dryer boasts high drying efficiency, answering to the need for production efficiency when the sugar prices drop.

It also uses relatively low amounts of energy and is highly durable. As such, it offers opportunities for manufacturers who wish to reduce their environmental impact and production costs.

A final advantage of the fluidized bed dryer is that sugar quality is never compromised. Stainless steel constructions guarantee a food-grade environment, and optimized drying conditions guarantee low moisture output, and therefore, high-quality sugar.

For these reasons, we believe sugar manufacturers are best off with this particular drying solution if they wish to satisfy sustainability-demanding customers and growth-expecting managers.

It is also the reason why Ventilex engineers focused their efforts on the optimization of the shaking fluidized bed dryer.

Get in touch

Ventilex Fluidized Bed Dryer

The Ventilex Fluid Bed Dryer dries and cools sugar through the ambient air.

In our Test Center (or at the client location), the optimal combination of airspeed and mechanical motion is determined. The sugar is then conveyed in the longitudinal direction of the dryer, and uniform results are achieved at lower temperatures and with shorter residence times. This makes the Ventilex Fluid Bed Dryer the most energy-efficient solution in its league.

The drying air is heated up by an indirect gas burner unit and heat exchanger. The exhaust air of the dryer is dedusted by a cyclone or filter. The process air will be blown off through the exhaust fan and/or recirculated to increase energy reductions.

Next, the dried sugar is collected in a conditioning silo. There, an integrated cooler section blows cool air through it for several days to reduce the sugar temperature.

The Ventilex Fluid Bed Dryer can be equipped with integrated WIP (Washing In Place) nozzles for a complete and efficient wet cleaning with a very short turnaround time.

All plants designed and supplied by Ventilex will enable you to obtain approvals put forward by the EU directives. We can also meet global regulations or standards.

Additional advantages of the Ventilex Fluid Bed Dryers:

- The design ensures that our installations meet the high food safety requirements of this industry.

- Our installations are completely made of stainless steel, and all the product contact parts are polished and welded.

- The quick-acting closures and the WIP system make the installation easy to disassemble and clean, enabling swift production resumption.

- Our installation is compact in size.

- We guarantee low energy consumption and no product loss.

- Compared to other drying equipment, installation and maintenance costs of our installation are lower.