Ventilex waste heat recovery

Transforming industrial waste heat into energy efficiency gains

In many industrial processes, valuable waste heat is still being released unused into the atmosphere. Ventilex offers a proven solution to turn this into an opportunity: we capture the waste heat and integrate it into our advanced drying and cooling systems, turning a lost resource into a powerful driver for energy savings and sustainability.

How does it work

Our Ventilex Fluid Bed Dryers are designed to harness waste heat from a wide range of industrial sources, such as:

- Kilns, cement, lime and other materials

- Industrial ovens, for example glass fiber or food processing

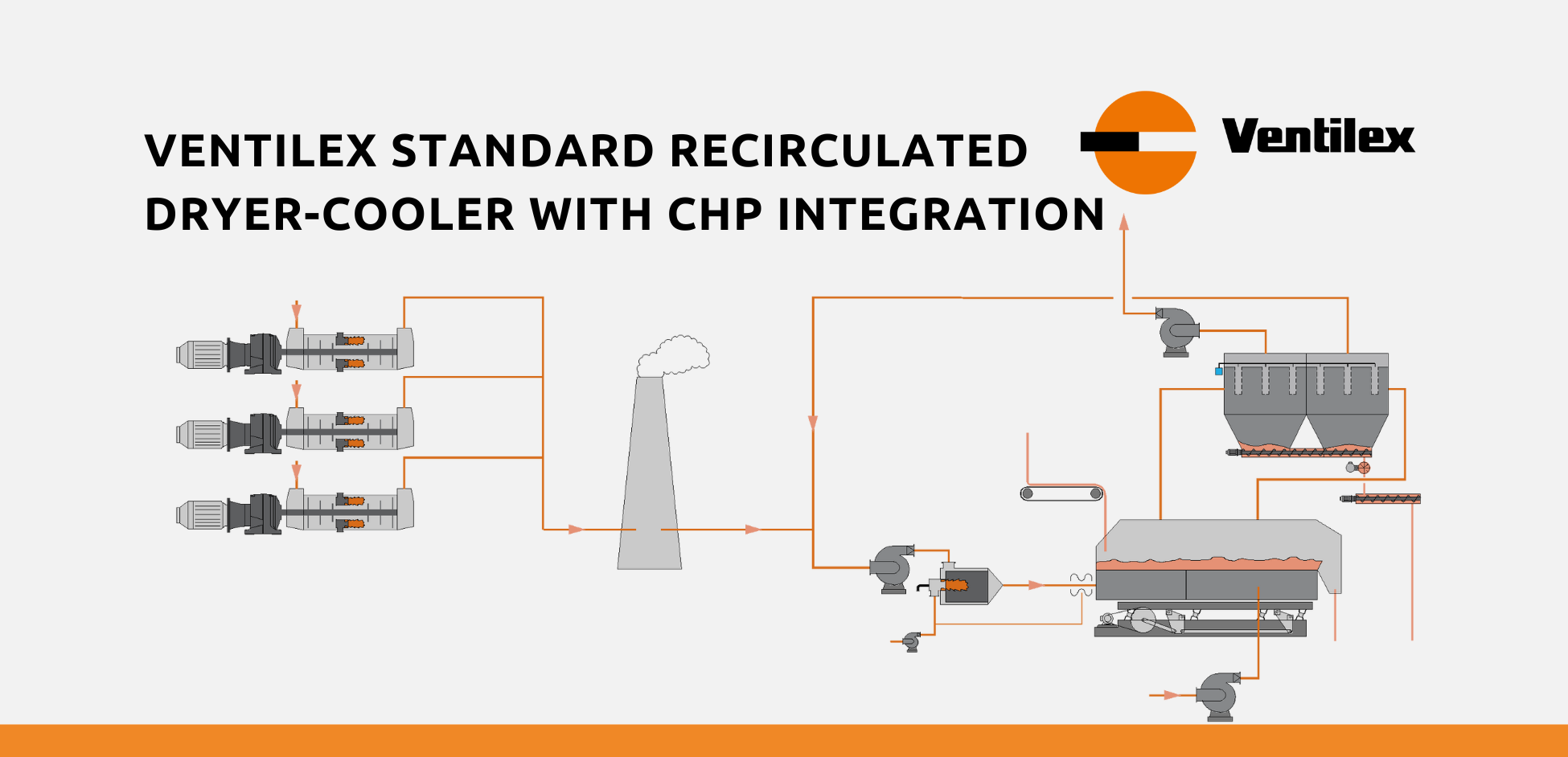

- Gas generators and CHP (Combined Heat Power) units

- Other process exhausts

Instead of venting this energy, we reuse it as the primary heat source for drying and cooling various products, from minerals and glass fibers to food ingredients and industrial by-products.

The benefits

- Energy efficiency, significantly reduce overall fossil fuel consumption and operational costs by integrating existing heat streams

- Sustainability, lower total CO₂ emissions and maximize the energy already available in your process

- Full-system reliability, Ventilex provides a complete solution: from engineering and integration to commissioning and long-term support

Proven across industries

Ventilex systems have successfully recovered and reused waste heat from kilns, bread ovens, gas generators etc. across diverse applications. Whether you process minerals, glass fibers, food products or specialty chemicals, our technology is flexible, scalable and tailored to your needs.

Let’s build a sustainable future together

Ready to give your waste heat a second life and make your production process more energy-efficient? Contact Ventilex, we will help you explore the possibilities for your plant and provide a complete engineering and operational setup.