Cut drying costs and emissions – discover your custom savings plan

Switch to smart fluid bed drying for minerals and reduce energy use by up to 35%. Let us show you how – based on your process.

Drying minerals is energy-intensive — but it doesn’t have to be.

Whether you’re drying sand, limestone, cement, or other aggregates, outdated systems are driving up your costs and carbon emissions.

At Ventilex, we help mineral processors like you reduce energy use and emissions — without compromising on drying performance or product quality.

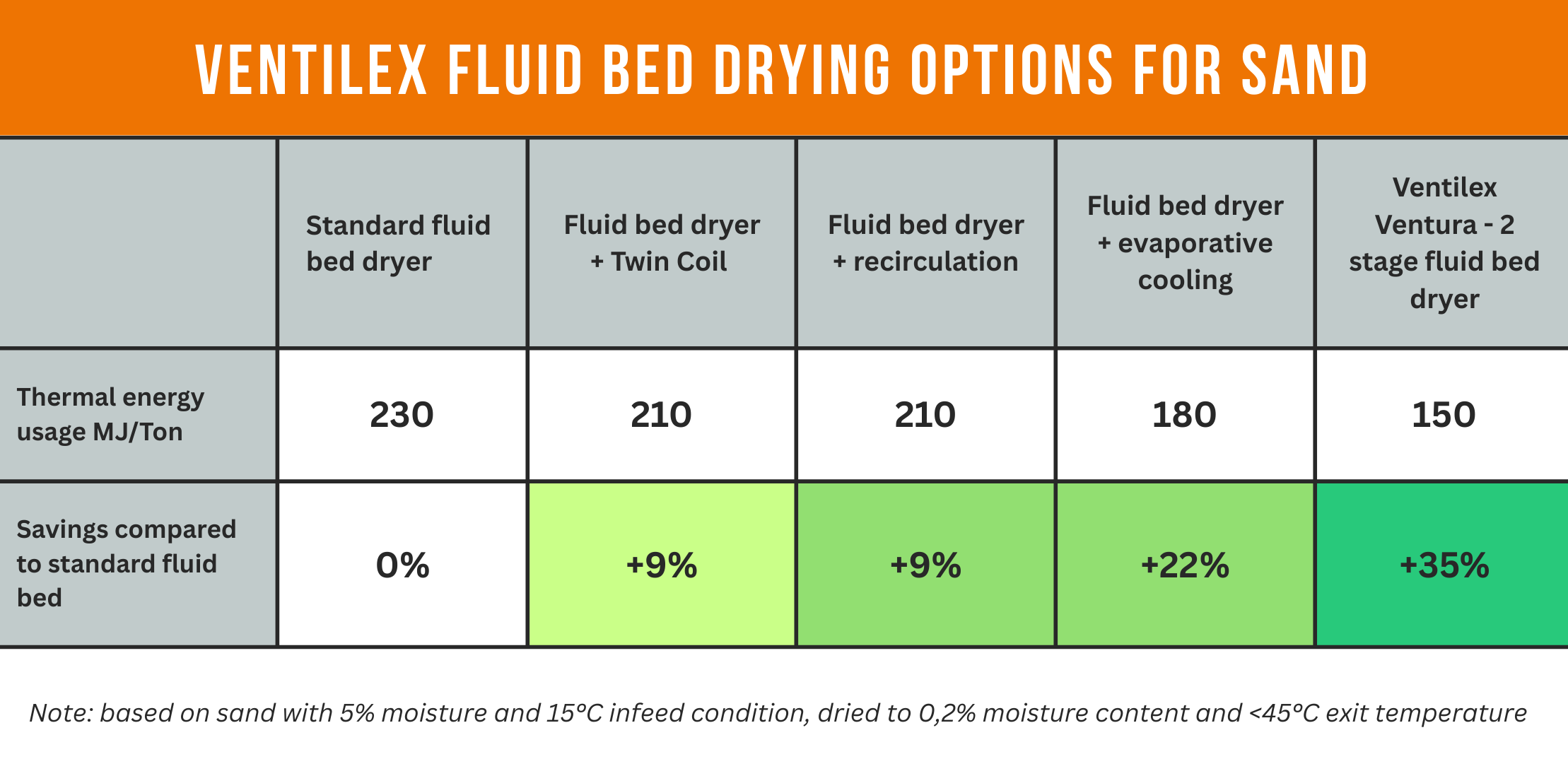

5 energy-smart fluid bed drying options — built around your process

Each step up delivers more savings. Here’s what we offer:

-

Standard fluid bed dryer

Baseline efficiency with uniform drying and gentle product handling. -

Fluid bed dryer with twin-coil system

Preheats air in the cooling zone for ~10% extra energy savings. -

Fluid bed dryer with recirculation

Reuses warm exhaust air — another ~10% energy reduction. -

Recirculation + evaporative cooling

Higher throughput, 20–25% less energy use. -

Ventilex Ventura (two-stage drying)

Max. efficiency: up to 35% energy savings and stable output temperature (~40°C).

+ Electric, heat pump, or hybrid heating options available

Reduce your carbon footprint even further and future-proof your process.

Get your savings plan

Ready to find out how much you can save?

Request your custom assessment and get clear insight into potential energy and emission reductions — based on your current setup.

✅ Proven energy savings

✅ Custom solutions for your material & process

✅ Fast, expert support — no obligation